PRODUCTS

Bleaching earth is the most important chemical utilized in the refining of oils & fats, where its function is to purify, decolorize and impart stability in the refined oil.

Although bleaching earth is primarily utilized in the refining of edible oils & fats, it is also widely used for refining non-edible oils, e.g. industrial triglycerides, transformer oil, mineral oils, paraffins and waxes.

There are many different types of edible oils that need to be treated, and the most appropriate bleaching earth or activated carbon blended bleaching earth to do the job depends on a number of factors, including; the type of oil, the type of refining utilized, the refining conditions, and the desired quality of the fully refined oil.

Natural Bleach Sdn Bhd produces Natural and Acid-Activated Bleaching Earths and their blends with Activated Carbons, to meet the needs of our customers, for today, and for the future.

Activated carbons assist in the removal of dioxins, PolyAromatic Hydrocarbons (PAHs), pigments, chlorine compounds and other undesirable materials.

PHYSICAL PROPERTIES

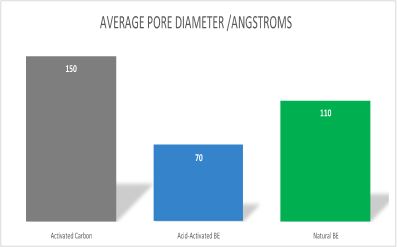

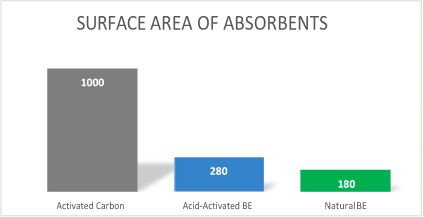

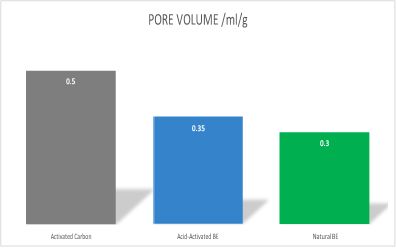

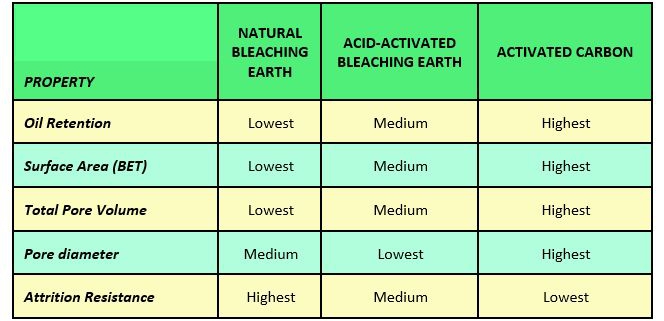

Activated Carbons have the highest Surface Area, greatest average Pore Diameter and Pore Volume, and can therefore absorb the greatest volume of large molecules.

Acid-Activated Bleaching Earths have higher Surface Areas , but lower Average Pore Diameter than Natural Bleaching Earths, therefore they can absorb a greater quantity of small molecules than natural bleaching earths.

Natural Bleaching Earths have larger Average Pore Diameters than Acid-Activated Bleaching Earths, therefore they have a greater capability to absorb larger molecules as compared with acid-activated bleaching earths.

Acid-Activated Bleaching Earths have higher Surface Areas , but lower Average Pore Diameter than Natural Bleaching Earths, therefore they can absorb a greater quantity of small molecules than natural bleaching earths.

Natural Bleaching Earths have larger Average Pore Diameters than Acid-Activated Bleaching Earths, therefore they have a greater capability to absorb larger molecules as compared with acid-activated bleaching earths.

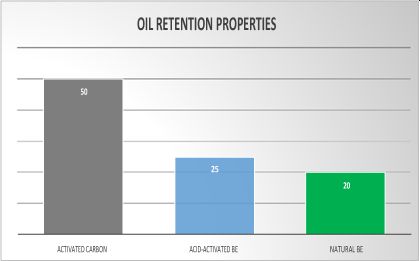

Oil-Retention Properties of Spent Absorbent

The retention of oil in the spent absorbent is an important factor in assessing the total costs for an absorbent.

For this reason, it is important to find a source of activated carbon that has the minimum possible level of oil retention.

Acid-activated bleaching earths also have higher oil retention as compared with “NB14000 Series” natural bleaching earths.

It should be noted that some competitors natural bleaching earths have high oil retention, making them much less desirable than our natural bleaching earths.

Structural Integrity

Natural clays have the strongest structures that resist attrition that may occur when bleaching materials are pneumatically conveyed & when they pass through pumps.

Acid-Activated Bleaching Earths have silica fronds that are formed during the acid-activation process. Hash handling may cause these fronds to break off resulting in loss of bleaching performance and may adversely affect filtration performance.

Activated Carbons are relatively soft materials and are most susceptible to particle-size deterioration during handling. The production of fines, and resulting fines breakthrough are important factors. The abrasion resistance is thus an important factor in the selection of activated carbons. We utilize steam-activated that have similar structural strength to acid-activated clays.

| COMPARISON OF THE PROPERTIES OF NATURAL BLEACHING EARTH, |

| ACID-ACTIVATED BLEACHING EARTH AND ACTIVATED CARBON |

Action of Absorbent

Natural Bleaching Earths & Activated Carbons primarily remove impurities by absorption, without affecting the other properties of the oil being processed. We utilize a blend of different activated carbons in order to achieve the desired structural strength and impurity removal performance.

Acid-Activated Bleaching Earths function as absorbents, and also have greater ion-exchange capacity and catalytic properties as compared with natural bleaching earths and activated carbons. Acid catalytic cracking can reduce the size of larger molecules, and protonation can cause structural changes that make certain pigments invisible.

GRADE SELECTION

Natural Bleaching Earths, Acid-Activated Bleaching Earths and Activated Carbons all have different properties. For this reason, the refiner must select which bleaching earth, or bleaching earth blended with activated carbon that is most appropriate for the oil being refined, to meet their desired properties for the fully refined oil. Our team are on hand to assist you with your grade selection.

Our bleaching earths are utilized to successfully refine a range of chemically- and physically- refined edible oils, including palm oil & its fractions, coconut oil, soyabean oil, Canola/rapeseed oil, groundnut oil, mustard seed oil, rice bran oil, cottonseed oil, and corn oil.

ENHANCING NATURE’S POTENTIAL

Natural Bleach’s “NB14000 Series” of Natural Non-Acidic Bleaching Earths are activated by physical processing natural clays to develop enhanced absorbent properties. In the process the clays are transformed into granules or free-flowing powders.

No chemicals are utilized in the processing, and no wastes are generated.

“NB14000 Series” bleaching earths act primarily as absorbents, removing impurities from the oil being processed, without otherwise affecting the oil. This distinguishes the “NB14000 Series of bleaching earths from classical acid-activated bleaching earths that can modify the oil through cracking and isomerization reactions.

PRESERVES NUTRITIONAL VALUE

“NB14000 Series” bleaching earths are absorbents that remove oxidized materials, gums, trace metals and pigments from the oil during the bleaching process.

The absence of catalytic activity preserves the structure of the oil, as there is no double bond shifting or conjugation that would cause a reduction in stability of the oil.

The lack of catalytic activity also means that harmful Trans-isomers are Not formed when utilizing “NB14000 Series” bleaching earth.

This important feature of the “NB14000 Series” of bleaching earths can be utilized in the processing of crude palm oil.

This important feature of the “NB14000 Series” of bleaching earths can be utilized in the processing of crude palm oil.

The Carotenoids can be substantially preserved in the oil during the bleaching stage, enabling stable and nutritionally beneficial “Red Palm Oil” to be produced, after deodorizing under mild conditions, or low-coloured oil under normal high-temperature deodorization.

LOW-CHLORIDE CONTENT

Since the clays that we utilize for the manufacture of our “NB14000 Series” bleaching earths have never been exposed to sea water, they are naturally very low in chloride and chlorine content. This greatly assists those refiners who wish to produce oils with the lowest possible contents of the harmful compounds known as 3-MCPDs.

Activated carbon blends have additional benefits in that they have enhanced removal properties for organo-chlorine compounds, including dioxins.

TYPICAL COMPOSITION OF MOST POPULAR GRADES |

||

PACKING

Our bleaching earths are available in 25kg multi-ply paper sacks, Jumbo bags (e.g. 1,000kg), and in some locations in bulk-powder tanker loads.

Pictures of 25kg paper bags, Jumbo baffle bags (on pallets), Powder tanker, and containerized packed product.

STORAGE

Bleaching earths and activated carbons are powerful absorbents, and should be stored in a clean, dry place away from any strong odours.